Door Closer and Floor Spring Guide

Which Door Closer?

All forms of ‘controlled door closing devices’ are covered by the harmonised European standard EN 1154. This provides details on product types by use, test cycles, door mass, corrosion resistance and product performance requirements using a 6-digit classification code. Illustrated is a Product Classification Guide that will provide additional information to help select the most suitable door closer for your application.

In addition to EN 1154 door closers may have also been third party tested which provides reassurance to specifiers and authorities that all aspects of the product’s testing, assessment and manufacturing have been checked and verified. This is performed by the Certifire Scheme at Warrington and products will be labelled accordingly.

CE Mark Explained

Door closers are an important link in the control of fire and smoke and their usage can help save lives. From July 2013 it became a legal requirement for all products which are covered by a harmonised EN standard to be CE marked before they can be placed on the market. For door closing devices, EN 1154 and EN 1155 became harmonised standards across Europe and are now the standards required in order to attain CE marking. Validation of the CE mark requires the production of a Declaration of Performance (DoP) by the manufacturer.

DOOR SIZE CHART - EN 1154

| Door closer size | Maximum Door Width | Maximum Door Weight |

|---|---|---|

| 1 | 750mm | 20kg |

| 2 | 850mm | 40kg |

| 3 | 950mm | 60kg |

| 4 | 110mm | 80kg |

| 5 | 1250mm | 100kg |

| 6 | 1400mm | 120kg |

| 7 | 1600mm | 160kg |

NOTE: For fire door applications, power size 3 is a minimum requirement.

FIG 1: DOOR MOUNTED PROJECTING ARM, PULL-SIDE

The most common application, provides a high degree of door control and range of adjustment. The closer is mounted on the pull side of the door with the arm mounted on the frame. When the door opens the arm passes over the door.

FIG 66: DOOR MOUNTED PARALLEL ARM, PUSH-SIDE

The closer is mounted on the push side of the door. When the door opens, the closer arm swings with the angle of the door. This position stops the closer protruding into the room and is suitable for use on narrow door frames.

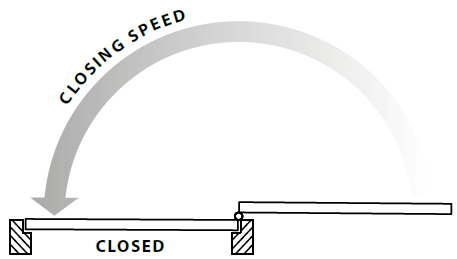

EN 1154 Product Classification Guide

This is the European standard for the performance of controlled door closing devices. It uses a 6 digit coding system to give clear details on the capabilities and performance levels of what the specific door closer model has been tested and approved to.

Detailed below is an explanation of what each number indicates.

Category of use (Box 1)

Defines the angle from which the device will close the door in a controlled manner.

- Grade 3 – 105°

- Grade 4 – 180°

Test cycles (Box 2)

Prescribes a series of test cycles. Only one grade is identified.

- Grade 8 – 500,000 cycles

Door mass/size (Box 3)

Defines the angle from which the device will close the door in a controlled manner.

Identifies the closer power size as defined by the door width and mass. Adjustable power closers are defined by their upper and lower power sizes. e.g. 5/2 (40 – 100kg)

Suitability for fire / smoke doors (Box 4)

Having successfully completed a fire test to EN 1634.

- Grade 1 – suitable for use on fire/smoke door assemblies

- Grade 0 – not suitable for use on fire/smoke door assemblies

Safety (Box 5)

Ensures the operation and suitability of the closer is hazard free – operates without risk to the user.

- Only Grade 1 is identified

Corrosion Resistance (Box 6)

Level of corrosion resistance to EN 1670 Neutral Salt Spray test and operation of the product at extreme temperatures. Five grades are identified.

- Grade 0: No identified resistance

- Grade 1: Mild resistance

- Grade 2: Moderate resistance

- Grade 3: High resistance

- Grade 4: Very high resistance (240 hours)

Door Closer Features

POWER SIZE

The Power Size of a door closer is measured in accordance with the Closing Torque that is achievable on the closing cycle.

The BS EN 1154 Standard classifies closers from a Size 1 through to a size 7 and recommends the use in accordance with the door width and door mass (weight).

Power Sizes can be fixed, selectable or adjustable.

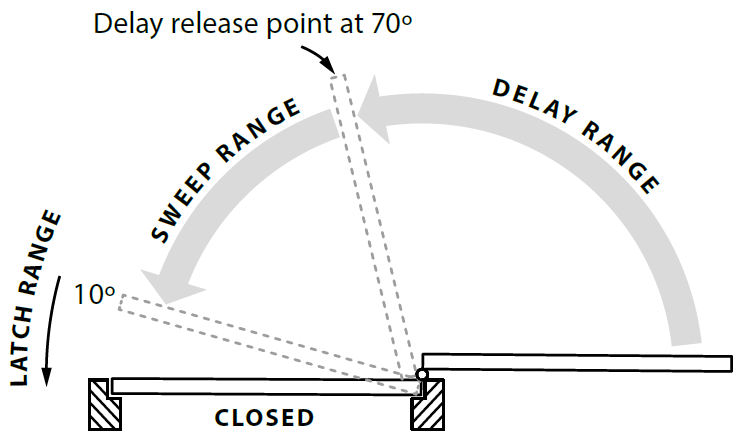

ADJUSTABLE CLOSING SPEED

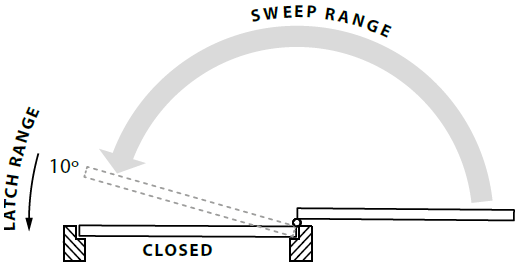

Controlled door closers offer adjustability to the speed that the door will operate, the closing speed has adjustment from the maximum opening angle through to the last 10 to 15°.

ADJUSTABLE LATCH ACTION

This allows speed adjustability on the last 10 to 15° to assist with overcoming latches and seals.

ADJUSTABLE BACKCHECK

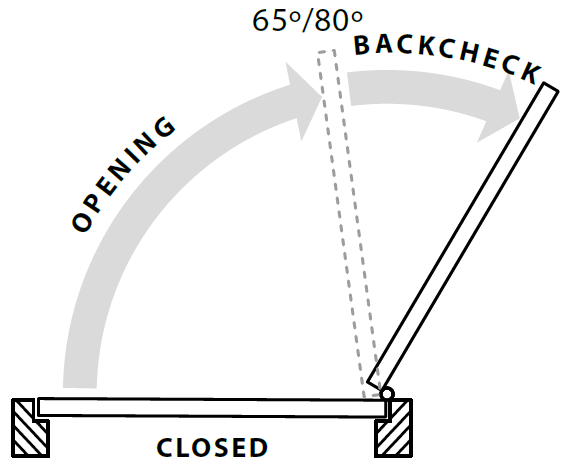

The backcheck function slows the speed of the door whilst in the opening cycle, the function is to prevent damage being caused to the door, associated hardware or adjacent walls in the event of the door being flung open (Backcheck is not an alternative to a door stop).

ADJUSTABLE DELAYED ACTION

The delayed action function slows the first part of the closing cycle down. Its function is particularly useful for disabled / elderly who may need additional time to pass through the doorway, delayed action normally releases around 70° where the standard closing speed will then commence.